Difference: TrackWork (1 vs. 14)

Revision 142023-07-16 - PeterSchmid

| Line: 1 to 1 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | |||||||||||||||||

| Line: 10 to 10 | |||||||||||||||||

|

Intro

| |||||||||||||||||

| Added: | |||||||||||||||||

| > > |

| ||||||||||||||||

| Line: 290 to 292 | |||||||||||||||||

|

| |||||||||||||||||

| Changed: | |||||||||||||||||

| < < | How To Build a Switch with CVT Turnout Ties | ||||||||||||||||

| > > | How To Build a HO Switch with CVT Turnout Ties | ||||||||||||||||

|

There is nothing wrong with the Turnout Kits | |||||||||||||||||

| Changed: | |||||||||||||||||

| < < |

| ||||||||||||||||

| > > |

| ||||||||||||||||

| Changed: | |||||||||||||||||

| < < |

| ||||||||||||||||

| > > |

| ||||||||||||||||

| |||||||||||||||||

| Line: 312 to 315 | |||||||||||||||||

| |||||||||||||||||

| Changed: | |||||||||||||||||

| < < |

| ||||||||||||||||

| > > |

| ||||||||||||||||

| Added: | |||||||||||||||||

| > > |

| ||||||||||||||||

| Line: 420 to 425 | |||||||||||||||||

| |||||||||||||||||

| Added: | |||||||||||||||||

| > > |

| ||||||||||||||||

Revision 132023-07-10 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | ||||||||

| Line: 284 to 284 | ||||||||

| ||||||||

| Added: | ||||||||

| > > | ||||||||

|

| ||||||||

| Changed: | ||||||||

| < < | Build a Switch with CVT Turnout Ties | |||||||

| > > | How To Build a Switch with CVT Turnout Ties | |||||||

| Changed: | ||||||||

| < < | There is nothing wrong with the Turnout Kits | |||||||

| > > | There is nothing wrong with the Turnout Kits | |||||||

|

| ||||||||

Revision 122023-07-09 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | ||||||||

| Line: 9 to 9 | ||||||||

|

Intro

| ||||||||

| Changed: | ||||||||

| < < | Intro | |||||||

| > > | ||||||||

| Line: 18 to 18 | ||||||||

| Changed: | ||||||||

| < < | Prototype

| |||||||

| > > | ||||||||

Prototype    | ||||||||

| Line: 48 to 48 | ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

Rails | ||||||||

| Line: 145 to 145 | ||||||||

| Changed: | ||||||||

| < < | Tips

| |||||||

| > > | ||||||||

TipsTools needed

| ||||||||

| Added: | ||||||||

| > > |

| |||||||

| ||||||||

| Line: 171 to 172 | ||||||||

| Changed: | ||||||||

| < < | How To Scratch Build a Narrow Gauge Standard Gauge Crossing

| |||||||

| > > | ||||||||

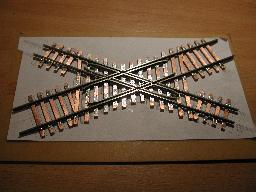

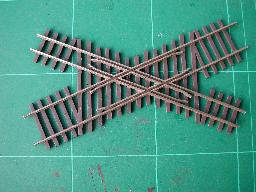

How To Scratch Build a Narrow Gauge Standard Gauge CrossingAs far as I know there is no commercial narrow gauge standard gauge crossing available. It takes me about 4 h to build a "diamond" from scratch. You need only only some code 70 rails and PCB cross ties. | ||||||||

| Line: 230 to 231 | ||||||||

| Changed: | ||||||||

| < < | How To Convert an Atlas N Code 55 Turnout to HOn30

| |||||||

| > > | ||||||||

How To Convert an Atlas N Code 55 Turnout to HOn30Commercial available HOn30/H0e/009 turnouts from Peco, Tillig, Technomodell, and Roco have too heavy rails (Code 80/83) and too wide angles (15 °, less than #4). You can build the turnouts from scratch, but for me it is difficult and to time-consuming to build the heel of the switch (especially the hinge) and the frog. The N code 55 turnouts from Atlas are available with frog numbers #5 and #7 (for details see http://www.atlasrr.com/Trackmisc/ncode55.htm | ||||||||

| Line: 285 to 286 | ||||||||

| Added: | ||||||||

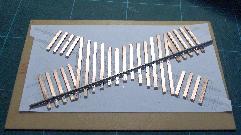

| > > | Build a Switch with CVT Turnout TiesThere is nothing wrong with the Turnout Kits

| |||||||

| Changed: | ||||||||

| < < | Bibliography

| |||||||

| > > | ||||||||

Bibliography

| ||||||||

| Line: 385 to 414 | ||||||||

| ||||||||

| Added: | ||||||||

| > > |

| |||||||

Revision 112023-07-09 - PeterSchmid

| Line: 1 to 1 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | |||||||||

| Line: 7 to 7 | |||||||||

| titlestyle="color:#F00000;" }% | |||||||||

| Deleted: | |||||||||

| < < | |||||||||

| Added: | |||||||||

| > > | Intro

Intro

Contents

| ||||||||

| Added: | |||||||||

| > > | |||||||||

| Changed: | |||||||||

| < < | Prototype | ||||||||

| > > | |||||||||

| |||||||||

| Line: 37 to 45 | |||||||||

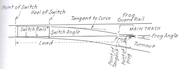

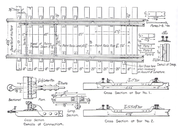

| Narrow gauge double slip switch. RhB Italy/Switzerland. | |||||||||

| Changed: | |||||||||

| < < | HOn30 Tracks | ||||||||

| > > | |||||||||

| Changed: | |||||||||

| < < | Rails | ||||||||

| > > | |||||||||

| One of the narrow gauge advantages was the use of lighter rails and therefore the lower investment. Lighter rail looks better and is more prototypical. The rails were 33' long til about 1925. | |||||||||

| Line: 72 to 84 | |||||||||

| A good compromise is to use code 55 rail for HOn30 and code 70 for standard gauge. Ties | |||||||||

| Changed: | |||||||||

| < < | Ties | ||||||||

| > > | Ties | ||||||||

| |||||||||

| Line: 120 to 132 | |||||||||

| FR-4 is a composite of a resin epoxy reinforced with a woven fiberglass mat (epoxy resin bonded glass fabric (ERBGF), Veroboard) printed circuit board (PCB) | |||||||||

| Changed: | |||||||||

| < < | Spikes | ||||||||

| > > | Spikes | ||||||||

Cut spikes are about 6" long, the spike head is about 1 9/16" x 1 5/16" in HO is this 1.75 x 0.46 x 0.38 mm. The small spikes from Micro Engineering are 8.0 x 1.7 x 1.0 mm, they are far too large. You can build your own spike from 0.4 mm wire, you have to drill holes into the ties too. That's why I omit the spikes.

| |||||||||

| Changed: | |||||||||

| < < | Tie Plates | ||||||||

| > > | Tie Plates | ||||||||

| Tie plates were not always used for narrow gauge tracks. But normally they were found at least on turnouts and in curves. They are 5" to 10" wide and about 1/2" (HO 0.15 mm) thick. Tie plates for HO are too small and too difficult to build for me. I omit tie plates on my tracks. | |||||||||

| Changed: | |||||||||

| < < | Tips | ||||||||

| > > | |||||||||

| Changed: | |||||||||

| < < | Tools needed | ||||||||

| > > | |||||||||

| |||||||||

| Line: 142 to 158 | |||||||||

| |||||||||

| Changed: | |||||||||

| < < | Soldering tips | ||||||||

| > > | Soldering tips | ||||||||

| |||||||||

| Line: 152 to 168 | |||||||||

| |||||||||

| Changed: | |||||||||

| < < | How To Scratch Build a Narrow Gauge Standard Gauge Crossing | ||||||||

| > > | |||||||||

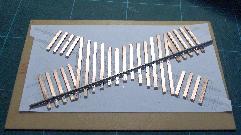

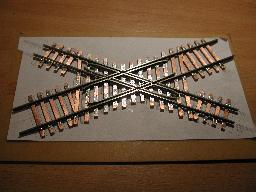

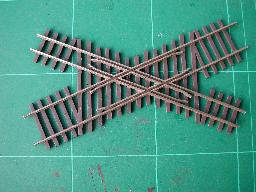

| As far as I know there is no commercial narrow gauge standard gauge crossing available. It takes me about 4 h to build a "diamond" from scratch. You need only only some code 70 rails and PCB cross ties. Step by step instructions to build a crossing from scratch: | |||||||||

| Changed: | |||||||||

| < < | Print out a template | ||||||||

| > > | Print out a template | ||||||||

e.g. from Fast Tracks " target="_blank">http://www.handlaidtrack.com/]] | |||||||||

| Changed: | |||||||||

| < < | Glue the crossties to the template | ||||||||

| > > | Glue the crossties to the template | ||||||||

For the first crossing I built, I used for every second tie a PCB tie. Now I use for all ties PCB ties.

| |||||||||

| Changed: | |||||||||

| < < | Solder the first rail from the mainline (usually the standard gauge leg) to the ties | ||||||||

| > > | Solder the first rail from the mainline (usually the standard gauge leg) to the ties | ||||||||

Solder the second rail to the ties, use a HO track gauge to ensure the right distance between the rails.

| |||||||||

| Changed: | |||||||||

| < < | Bend the two guard rails for the mainline and solder the rails next to the mainline rails | ||||||||

| > > | Bend the two guard rails for the mainline and solder the rails next to the mainline rails | ||||||||

Check the flangeways with a NMRA HO gauge.

| |||||||||

| Changed: | |||||||||

| < < | Bevel the end of a rail and solder the first crossing rail to the ties and to mainline rail | ||||||||

| > > | Bevel the end of a rail and solder the first crossing rail to the ties and to mainline rail | ||||||||

The rail heads should touch each other, to achive this I remove about 1 mm from the base of the crossing rail. Solder second crossing rail to the ties and to mainline rail, use N track gauge to ensure the right distance between the rails.

| |||||||||

| Changed: | |||||||||

| < < | Cut and bevel a rail to the length between the two mainline guardrails | ||||||||

| > > | Cut and bevel a rail to the length between the two mainline guardrails | ||||||||

| Use a straight edge to guide the rail and solder the rail to the ties. Finish the crossing rails | |||||||||

| Changed: | |||||||||

| < < | Bend the outer guard rails for the narrow gauge line with a needle nose pliers | ||||||||

| > > | Bend the outer guard rails for the narrow gauge line with a needle nose pliers | ||||||||

| Bevel the ends and solder the rails to the PCB ties. Insert the inner guard rails for the narrow gauge line. | |||||||||

| Changed: | |||||||||

| < < | Cut the mainline rails and the guard rails for the HOn30 flangeways with a cutting disc moto tool. | ||||||||

| > > | Cut the mainline rails and the guard rails for the HOn30 flangeways with a cutting disc moto tool. | ||||||||

| |||||||||

| Changed: | |||||||||

| < < | Put the crossing in warm soapy water and remove the crossing from the PCB | ||||||||

| > > | Put the crossing in warm soapy water and remove the crossing from the PCB | ||||||||

Cut the isolating gaps with the fretsaw trough the rails and the ties.

| |||||||||

| Changed: | |||||||||

| < < | How To Convert an Atlas N Code 55 Turnout to HOn30 | ||||||||

| > > | |||||||||

|

Commercial available HOn30/H0e/009 turnouts from Peco, Tillig, Technomodell, and Roco have too heavy rails (Code 80/83) and too wide angles (15 °, less than #4). You can build the turnouts from scratch, but for me it is difficult and to time-consuming to build the heel of the switch (especially the hinge) and the frog. The N code 55 turnouts from Atlas are available with frog numbers #5 and #7 (for details see http://www.atlasrr.com/Trackmisc/ncode55.htm | |||||||||

| Changed: | |||||||||

| < < | Print out a template | ||||||||

| > > | Print out a template | ||||||||

|

e.g. from Fast Tracks " target="_blank">http://www.handlaidtrack.com/]] | |||||||||

| Changed: | |||||||||

| < < | Remove the rails from the plastic ties | ||||||||

| > > | Remove the rails from the plastic ties | ||||||||

| Remove the pins from the frog and the guard rails. | |||||||||

| Changed: | |||||||||

| < < | Glue the crossties to the template | ||||||||

| > > | Glue the crossties to the template | ||||||||

| Changed: | |||||||||

| < < | Solder the straight stock rail to the ties | ||||||||

| > > | Solder the straight stock rail to the ties | ||||||||

Use a straight edge as a guide.

| |||||||||

| Changed: | |||||||||

| < < | Solder the frog to the ties | ||||||||

| > > | Solder the frog to the ties | ||||||||

| Use a NMRA N gauge to check the distance between the stock rail an the frog. The lead (distance between toe of point and frog point) is 75 mm. | |||||||||

| Changed: | |||||||||

| < < | Solder the second stock rail to the ties | ||||||||

| > > | Solder the second stock rail to the ties | ||||||||

| Check the gauge between the stock rails and between the stock rail and the frog. | |||||||||

| Changed: | |||||||||

| < < | Solder the two rails to the frog heel (frog point rail) and to the frog toe (closure rails) | ||||||||

| > > | Solder the two rails to the frog heel (frog point rail) and to the frog toe (closure rails) | ||||||||

Use a N track gauges to ensure the right distance between the rails. Solder the two guard rails to the rails.

| |||||||||

| Changed: | |||||||||

| < < | Solder the switch tabs to the heel of the point | ||||||||

| > > | Solder the switch tabs to the heel of the point | ||||||||

| Make sure that the rails are in line. | |||||||||

| Changed: | |||||||||

| < < | Cut gaps into the copper foil ties | ||||||||

| > > | Cut gaps into the copper foil ties | ||||||||

| |||||||||

| Changed: | |||||||||

| < < | Put the turnout in warm soapy water and remove the turnout from the PCB. | ||||||||

| > > | Put the turnout in warm soapy water and remove the turnout from the PCB. | ||||||||

Fill the gaps with filler, sand and paint the turnout.

| |||||||||

| Changed: | |||||||||

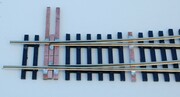

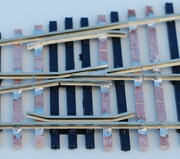

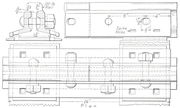

| < < | HOn30 #5 Turnout in Comparison With Shinohara HO #6 Code 100 | ||||||||

| > > | HOn30 #5 Turnout in Comparison With Shinohara HO #6 Code 100 | ||||||||

| |||||||||

| Changed: | |||||||||

| < < | Bibliography | ||||||||

| > > | |||||||||

| |||||||||

| Line: 270 to 299 | |||||||||

| Added: | |||||||||

| > > | |||||||||

| Added: | |||||||||

| > > | |||||||||

-- PeterSchmid - 2011-05-09

| |||||||||

| Line: 349 to 381 | |||||||||

| |||||||||

| Added: | |||||||||

| > > |

| ||||||||

Revision 102023-06-17 - PeterSchmid

| Line: 1 to 1 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | ||||||||||||||||

| Line: 48 to 48 | ||||||||||||||||

| ||||||||||||||||

| Added: | ||||||||||||||||

| > > |

| |||||||||||||||

| ||||||||||||||||

Revision 92018-12-27 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | ||||||||

| Line: 272 to 272 | ||||||||

| -- PeterSchmid - 2011-05-09 | ||||||||

| Added: | ||||||||

| > > |

This work by Peter Schmid is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License. | |||||||

| ||||||||

Revision 82018-12-02 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

%DASHBOARD{ section="banner" | ||||||||

| Line: 263 to 263 | ||||||||

| ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| ||||||||

| Changed: | ||||||||

| < < | ||||||||

| > > | ||||||||

| -- PeterSchmid - 2011-05-09 | ||||||||

Revision 72015-03-01 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| ||||||||

| Changed: | ||||||||

| < < | HOn30 Trackwork Mini HowTo | |||||||

| > > |

HOn30 Trackwork Mini HowTo

| |||||||

| Line: 336 to 343 | ||||||||

| ||||||||

| Added: | ||||||||

| > > |

| |||||||

Revision 62013-11-01 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

HOn30 Trackwork Mini HowTo | ||||||||

| Line: 98 to 98 | ||||||||

| PCB ties are about 1.6 mm / 1/16" thick) | ||||||||

| Changed: | ||||||||

| < < | Fast Track HO narrow gauge PCB crossties (in HOn30 templates):

| |||||||

| > > | Fast Track HO narrow gauge PCB crossties:

| |||||||

| PCB crossties are 13-1/2 scale feet long by 7 scale inches wide (.080"), and are available in 1/16" and 1/32" thickness. | ||||||||

| Changed: | ||||||||

| < < | I cut my ties from a 1.6 x 100 x 160 mm printed circuit board PCB (in Switzerland it is available from Distrelec, Partnumber 450335, for 2.50 CHF that's about $2). I prefer FR-2 PCBs, because the FR-4 (glass/epoxy) makes your sawing blades dull. I saw about 2.3 mm stripes from the PCB with a fretsaw and cut the ties to length (20 mm) with a wire cutting pliers. I choose 8 mm center-to-center distance for my pike. | |||||||

| > > | I cut my ties from a 1.6 x 100 x 160 mm printed circuit board PCB (in Switzerland it is available from Distrelec, Partnumber 450335, for 2.50 CHF that's about $2). I prefer FR-2 PCBs, because the FR-4 (glass/epoxy) makes your sawing blades dull. I saw about 2.3 mm stripes from the PCB with a fretsaw and cut the ties to length (20 mm) with a wire cutting pliers. I choose 8 mm (27" prototype) center-to-center distance for my pike. The Fast Track choose 24" for branch and 21" for main line. | |||||||

| The Micro Engineering ties have about the same thickness and width and can be used together with my PCB ties. It's enough to insert a PCB tie for about every 4th tie. | ||||||||

Revision 52011-05-13 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

HOn30 Trackwork Mini HowTo | ||||||||

| Line: 261 to 261 | ||||||||

| Deleted: | ||||||||

| < < |  | |||||||

| -- PeterSchmid - 2011-05-09 | ||||||||

Revision 42011-05-12 - PeterSchmid

| Line: 1 to 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

HOn30 Trackwork Mini HowTo | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 6 to 6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

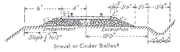

Prototype | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < |

Standard gauge trackwork somewhere in New England. Wood ties

and nails are still used in 1996. You can see a rail anchor in

the third picture, a detail very seldom modelled.

Standard gauge trackwork somewhere in New England. Wood ties

and nails are still used in 1996. You can see a rail anchor in

the third picture, a detail very seldom modelled.

A friend gave me some photos from the 3 foot narrow gauge

railroad White Pass and Yukon Route. Maybe original tracks from

1898.

A friend gave me some photos from the 3 foot narrow gauge

railroad White Pass and Yukon Route. Maybe original tracks from

1898.

You can see a 76 cm narrow gauge line crossing two standard

gauge tracks in Weiz, Austria. The Switch is in Bikfeld. The

trackwork looks very american for my opinion.

You can see a 76 cm narrow gauge line crossing two standard

gauge tracks in Weiz, Austria. The Switch is in Bikfeld. The

trackwork looks very american for my opinion.

Some industrial 60 cm and 75 cm gauge trackwork in

Switzerland.

Some industrial 60 cm and 75 cm gauge trackwork in

Switzerland.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |     | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | Waldenburger Bahn, the only 75 cm gauge commuter train in Switzerland (probably in the world). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | Standard gauge trackwork somewhere in New England. Wood ties and nails are still used in 1996. You can see a rail anchor in the third picture, a detail very seldom modelled. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |    A friend gave me some photos from the 3 foot narrow gauge railroad White Pass and Yukon Route. Maybe original tracks from 1898.

A friend gave me some photos from the 3 foot narrow gauge railroad White Pass and Yukon Route. Maybe original tracks from 1898.

You can see a 76 cm narrow gauge line crossing two standard gauge tracks in Weiz, Austria. The Switch is in Bikfeld. The trackwork looks very american for my opinion.

You can see a 76 cm narrow gauge line crossing two standard gauge tracks in Weiz, Austria. The Switch is in Bikfeld. The trackwork looks very american for my opinion.

Some industrial 60 cm and 75 cm gauge trackwork in Switzerland.

Some industrial 60 cm and 75 cm gauge trackwork in Switzerland.

Waldenburger Bahn, the only 75 cm gauge commuter train in Switzerland (probably in the world).

Waldenburger Bahn, the only 75 cm gauge commuter train in Switzerland (probably in the world).

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Narrow gauge double slip switch. RhB Italy/Switzerland. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 67 to 47 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 80 lb. rail from A.S.C.E: height 5" (HO 1.46 mm), base 5" (HO 1.46 mm), this corresponds in HO to code 55, 100 lb. corresponds in HO to code 70. Early narrow gauge lines used 40 lb. and lighter rail. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Quotation from Maine Two Footers On2 FAQ: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 81 to 61 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | A good compromise is to use code 55 rail for HOn30 and code 70 for standard gauge. Ties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | A good compromise is to use code 55 rail for HOn30 and code 70 for standard gauge. Ties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |

Ties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Deleted: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < |

Ties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PRR practice (standard gauge)

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 104 to 82 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Campbell Ties:

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 129 to 111 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| FR-4 is a composite of a resin epoxy reinforced with a woven fiberglass mat (epoxy resin bonded glass fabric (ERBGF), Veroboard) printed circuit board (PCB) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Deleted: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

SpikesCut spikes are about 6" long, the spike head is about 1 9/16" x 1 5/16" in HO is this 1.75 x 0.46 x 0.38 mm. The small spikes from Micro Engineering are 8.0 x 1.7 x 1.0 mm, they are far too large. You can build your own spike from 0.4 mm wire, you have to drill holes into the ties too. That's why I omit the spikes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tie Plates | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 164 to 143 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Deleted: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

How To Scratch Build a Narrow Gauge Standard Gauge CrossingAs far as I know there is no commercial narrow gauge standard gauge crossing available. It takes me about 4 h to build a "diamond" from scratch. You need only only some code 70 rails and PCB cross ties. Step by step instructions to build a crossing from scratch: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | Print out a template, e.g. from Fast Tracks http://www.handlaidtrack.com/ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | Print out a templatee.g. from Fast Tracks " target="_blank">http://www.handlaidtrack.com/]]

Glue the crossties to the templateFor the first crossing I built, I used for every second tie a PCB tie. Now I use for all ties PCB ties.

Solder the first rail from the mainline (usually the standard gauge leg) to the tiesSolder the second rail to the ties, use a HO track gauge to ensure the right distance between the rails.

Bend the two guard rails for the mainline and solder the rails next to the mainline railsCheck the flangeways with a NMRA HO gauge. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |

Bevel the end of a rail and solder the first crossing rail to the ties and to mainline railThe rail heads should touch each other, to achive this I remove about 1 mm from the base of the crossing rail. Solder second crossing rail to the ties and to mainline rail, use N track gauge to ensure the right distance between the rails.

Cut and bevel a rail to the length between the two mainline guardrailsUse a straight edge to guide the rail and solder the rail to the ties. Finish the crossing railsBend the outer guard rails for the narrow gauge line with a needle nose pliersBevel the ends and solder the rails to the PCB ties. Insert the inner guard rails for the narrow gauge line.Cut the mainline rails and the guard rails for the HOn30 flangeways with a cutting disc moto tool.

Put the crossing in warm soapy water and remove the crossing from the PCBCut the isolating gaps with the fretsaw trough the rails and the ties. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

How To Convert an Atlas N Code 55 Turnout to HOn30Commercial available HOn30/H0e/009 turnouts from Peco, Tillig, Technomodell, and Roco have too heavy rails (Code 80/83) and too wide angles (15 °, less than #4). You can build the turnouts from scratch, but for me it is difficult and to time-consuming to build the heel of the switch (especially the hinge) and the frog. The N code 55 turnouts from Atlas are available with frog numbers #5 and #7 (for details see http://www.atlasrr.com/Trackmisc/ncode55.htm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | Print out a template, e.g. from Fast Tracks http://www.handlaidtrack.com/ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | Print out a templatee.g. from Fast Tracks " target="_blank">http://www.handlaidtrack.com/]]Remove the rails from the plastic tiesRemove the pins from the frog and the guard rails.Glue the crossties to the templateSolder the straight stock rail to the tiesUse a straight edge as a guide.

Solder the frog to the tiesUse a NMRA N gauge to check the distance between the stock rail an the frog. The lead (distance between toe of point and frog point) is 75 mm.Solder the second stock rail to the tiesCheck the gauge between the stock rails and between the stock rail and the frog.Solder the two rails to the frog heel (frog point rail) and to the frog toe (closure rails)Use a N track gauges to ensure the right distance between the rails. Solder the two guard rails to the rails.

Solder the switch tabs to the heel of the pointMake sure that the rails are in line.Cut gaps into the copper foil ties | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | Solder the frog to the ties. Use a NMRA N gauge to check the distance between the stock rail an the frog. The lead (distance between toe of point and frog point) is 75 mm. Solder the second stock rail to the ties. Check the gauge between the stock rails and between the stock rail and the frog. Solder the two rails to the frog heel (frog point rail) and to the frog toe (closure rails). Use a N track gauges to ensure the right distance between the rails. Solder the two guard rails to the rails. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | Put the turnout in warm soapy water and remove the turnout from the PCB. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | Solder the switch tabs to the heel of the point. Make sure that the rails are in line. Cut gaps into the copper foil ties. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | Fill the gaps with filler, sand and paint the turnout. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | Put the turnout in warm soapy water and remove the turnout from the PCB. Fill the gaps with filler, sand and paint the turnout. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Changed: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| < < | HOn30 #5 Turnout in Comparison With Shinohara HO #6 Code 100 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | HOn30 #5 Turnout in Comparison With Shinohara HO #6 Code 100 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |   | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | Bibliography | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -- PeterSchmid - 2011-05-09 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Line: 238 to 304 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revision 32011-05-12 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

HOn30 Trackwork Mini HowTo | ||||||||

| Line: 109 to 109 | ||||||||

| overhang (5-2)/2 = 1 1/2" Campbell Ties: | ||||||||

| Changed: | ||||||||

| < < | 1.3 x 2.4 x 28 mm HO standard gauge 1.3 x 2.4 x 21 mm H0n3 They are relative thin, to prevent splitting (nails), less gravel is needed to cover the ground. | |||||||

| > > |

| |||||||

| Changed: | ||||||||

| < < | Micro Engineering full profile Ties: 1.7 x 2.3 x 23.5 mm HOn3 (37-103) | |||||||

| > > | Micro Engineering full profile Ties (37-103):

| |||||||

| PCB ties are about 1.6 mm / 1/16" thick) | ||||||||

| Changed: | ||||||||

| < < | Fast Track HO narrow gauge PCB crossties: 1.6 x 2.0 x 21 mm (in HOn30 templates) | |||||||

| > > | Fast Track HO narrow gauge PCB crossties (in HOn30 templates):

| |||||||

| PCB crossties are 13-1/2 scale feet long by 7 scale inches wide (.080"), and are available in 1/16" and 1/32" thickness. I cut my ties from a 1.6 x 100 x 160 mm printed circuit board PCB (in Switzerland it is available from Distrelec, Partnumber 450335, for 2.50 CHF that's about $2). I prefer FR-2 PCBs, because the FR-4 (glass/epoxy) makes your sawing blades dull. I saw about 2.3 mm stripes from the PCB with a fretsaw and cut the ties to length (20 mm) with a wire cutting pliers. I choose 8 mm center-to-center distance for my pike. | ||||||||

| Line: 128 to 128 | ||||||||

| FR-2 is composite material made of paper impregnated with a plasticized phenol formaldehyde resin (Synthetic Resin Bonded Paper (SRBP), Bakelite, Lamitex, Paxoline, Pertinax) FR-4 is a composite of a resin epoxy reinforced with a woven fiberglass mat (epoxy resin bonded glass fabric (ERBGF), Veroboard) printed circuit board (PCB) | ||||||||

| Changed: | ||||||||

| < < | Spikes | |||||||

| > > |

Spikes | |||||||

| Cut spikes are about 6" long, the spike head is about 1 9/16" x 1 5/16" in HO is this 1.75 x 0.46 x 0.38 mm. The small spikes from Micro Engineering are 8.0 x 1.7 x 1.0 mm, they are far too large. You can build your own spike from 0.4 mm wire, you have to drill holes into the ties too. That's why I omit the spikes. | ||||||||

| Added: | ||||||||

| > > |

Tie PlatesTie plates were not always used for narrow gauge tracks. But normally they were found at least on turnouts and in curves. They are 5" to 10" wide and about 1/2" (HO 0.15 mm) thick. Tie plates for HO are too small and too difficult to build for me. I omit tie plates on my tracks.TipsTools needed

Soldering tips

How To Scratch Build a Narrow Gauge Standard Gauge CrossingAs far as I know there is no commercial narrow gauge standard gauge crossing available. It takes me about 4 h to build a "diamond" from scratch. You need only only some code 70 rails and PCB cross ties. Step by step instructions to build a crossing from scratch: Print out a template, e.g. from Fast Tracks http://www.handlaidtrack.com/How To Convert an Atlas N Code 55 Turnout to HOn30Commercial available HOn30/H0e/009 turnouts from Peco, Tillig, Technomodell, and Roco have too heavy rails (Code 80/83) and too wide angles (15 °, less than #4). You can build the turnouts from scratch, but for me it is difficult and to time-consuming to build the heel of the switch (especially the hinge) and the frog. The N code 55 turnouts from Atlas are available with frog numbers #5 and #7 (for details see http://www.atlasrr.com/Trackmisc/ncode55.htm | |||||||

-- PeterSchmid - 2011-05-09

| ||||||||

| Line: 171 to 236 | ||||||||

| ||||||||

| Added: | ||||||||

| > > |

| |||||||

Revision 22011-05-11 - PeterSchmid

| Line: 1 to 1 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > | HOn30 Trackwork Mini HowToPrototype

Standard gauge trackwork somewhere in New England. Wood ties

and nails are still used in 1996. You can see a rail anchor in

the third picture, a detail very seldom modelled.

Standard gauge trackwork somewhere in New England. Wood ties

and nails are still used in 1996. You can see a rail anchor in

the third picture, a detail very seldom modelled.

A friend gave me some photos from the 3 foot narrow gauge

railroad White Pass and Yukon Route. Maybe original tracks from

1898.

A friend gave me some photos from the 3 foot narrow gauge

railroad White Pass and Yukon Route. Maybe original tracks from

1898.

You can see a 76 cm narrow gauge line crossing two standard

gauge tracks in Weiz, Austria. The Switch is in Bikfeld. The

trackwork looks very american for my opinion.

You can see a 76 cm narrow gauge line crossing two standard

gauge tracks in Weiz, Austria. The Switch is in Bikfeld. The

trackwork looks very american for my opinion.

Some industrial 60 cm and 75 cm gauge trackwork in

Switzerland.

Some industrial 60 cm and 75 cm gauge trackwork in

Switzerland.

Waldenburger Bahn, the only 75 cm gauge commuter train in

Switzerland (probably in the world).

Waldenburger Bahn, the only 75 cm gauge commuter train in

Switzerland (probably in the world).

Narrow gauge double slip switch. RhB Italy/Switzerland.

Narrow gauge double slip switch. RhB Italy/Switzerland.

HOn30 TracksRailsOne of the narrow gauge advantages was the use of lighter rails and therefore the lower investment. Lighter rail looks better and is more prototypical. The rails were 33' long til about 1925.

Quotation from Maine Two Footers On2 FAQ:

Quotation from Maine Two Footers On2 FAQ:

TiesPRR practice (standard gauge)

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| -- PeterSchmid - 2011-05-09 \ No newline at end of file | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Added: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| > > |

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revision 12011-05-09 - PeterSchmid

| Line: 1 to 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Added: | ||||||||

| > > |

| |||||||

View topic | History: r14 < r13 < r12 < r11 | More topic actions...

Ideas, requests, problems regarding TWiki? Send feedback